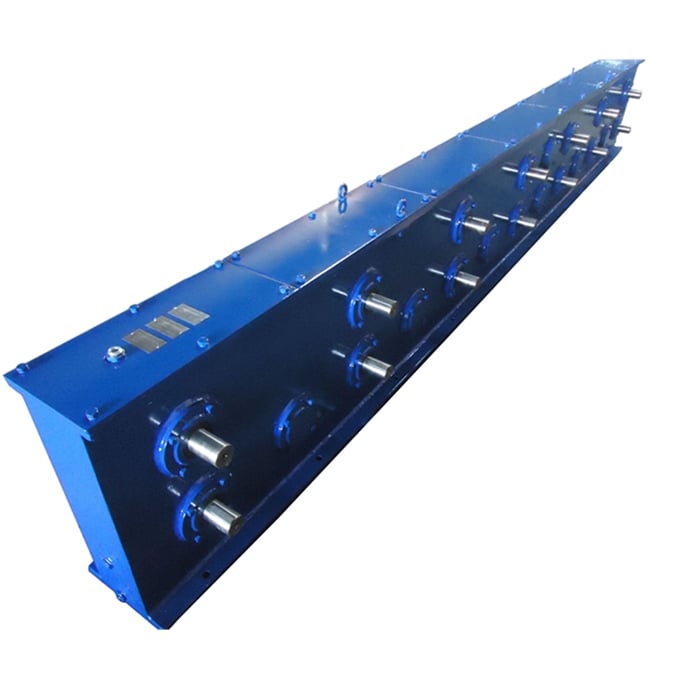

Product Description

Nmrv Worm Transmission Reductor Applied for Worm Speed Gearbox

Characteristics:

(1)Large output torque

(2) Safe, reliable, economical and durable

(3) Stable transmission, quiet operation

(4) High heat-radiating efficiency, high carrying ability

(5) Combination of 2 single-step worm gear speed reducers, meeting the requirements of super speed ratio

(6) Mechanical gearboxes are widely used in the sectors,like foodstuff, ceramics, and chemical manufacturing, as well as packing, printing, dyeing and plastics

Technical data:

(1) Motor input power:0.06kw-15kw

(2) Output torque:17-1971N.M

(3) Speed ratio of worm gear peed reducer: 5/10/15/20/25/30/40/50/60/80/100

(4) With IEC motor input flange: 56B14/71B14/80B5/90B5

Materials:

(1) NMRV571-NMRV090: Aluminium alloy housing

(2) NMRV110-150: Cast iron housing

(3) Bearing: CHINAMFG bearing & Homemade bearing

(4) Lubricant: Synthetic & Mineral

(5) The material of the worm mandrel is HT250, and the worm ring gear is ZQSn10-1.

(6) With high quality homemade bearings, assembled CHINAMFG oil seals & filled with high quality lubricant.

Operation&mantenance

(1)When worm speed reducer starts to work up to200-400 hours, its lubricant should be replaced.

(2)The gearbox need to replace the oil after 4000 hours.

(3)Worm reduction gearbox is fully filled with lubricant oil after finshed assembly.

(4)Lubricanting oil should be kept enough in the casing and checked at a fixed time.

Color:

(1) Blue / Light blue

(2) Silvery White

Quality control

(1) Quality guarantee: 1 year

(2) Certificate of quality: ISO9001:2000

(3) Every product must be tested before sending

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Industry |

| Spiral Line: | Right-Handed Rotation |

| Head: | Single Head |

| Reference Surface: | Conical Surface |

| Type: | Worm and Wormwheel |

| Samples: |

US$ 35/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do electronic or computer-controlled components integrate with winch drives in modern applications?

In modern applications, electronic or computer-controlled components play a crucial role in enhancing the functionality, precision, and safety of winch drives. These components integrate with winch drives to provide advanced control, monitoring, and automation capabilities. Here’s a detailed explanation of how electronic or computer-controlled components integrate with winch drives in modern applications:

- Control Systems:

Electronic or computer-controlled components are used to create sophisticated control systems for winch drives. These control systems allow operators to precisely control the speed, direction, and position of the winch drive. By integrating sensors, actuators, and feedback mechanisms, the control system can monitor the operating conditions and adjust parameters in real-time to optimize performance. Control systems may include programmable logic controllers (PLCs), microcontrollers, or dedicated electronic control units (ECUs) that communicate with the winch drive to execute commands and maintain desired operating parameters.

- Human-Machine Interfaces (HMIs):

Electronic components enable the integration of intuitive and user-friendly Human-Machine Interfaces (HMIs) with winch drives. HMIs provide a visual interface for operators to interact with the winch drive system. Touchscreen displays, buttons, switches, and graphical user interfaces (GUIs) allow operators to input commands, monitor system status, and access diagnostic information. HMIs also facilitate the adjustment of control parameters, alarm settings, and operational modes. The integration of HMIs enhances operator control and simplifies the operation of winch drives in modern applications.

- Sensors and Feedback Systems:

Electronic sensors are employed to gather real-time data about various parameters related to the winch drive and the operating environment. These sensors can measure variables such as load weight, cable tension, speed, temperature, and motor current. The collected data is then fed back to the control system, allowing it to make informed decisions and adjustments. For example, if the load exceeds a predefined limit, the control system can send a signal to stop the winch drive or activate an alarm. Sensors and feedback systems ensure accurate monitoring of operating conditions and enable proactive control and safety measures.

- Communication Protocols:

Electronic or computer-controlled components facilitate communication between winch drives and other devices or systems. Modern winch drives often support various communication protocols, such as Ethernet, CAN bus, Modbus, or Profibus, which enable seamless integration with higher-level control systems, supervisory systems, or industrial networks. This integration allows for centralized control, remote monitoring, and data exchange between the winch drive and other components or systems, enhancing coordination and automation in complex applications.

- Automation and Programmability:

Electronic or computer-controlled components enable advanced automation and programmability features in winch drives. With the integration of programmable logic controllers (PLCs) or microcontrollers, winch drives can execute pre-programmed sequences of operations, follow specific load profiles, or respond to external commands and triggers. Automation reduces manual intervention, improves efficiency, and enables synchronized operation with other equipment or systems. Programmability allows customization and adaptation of winch drive behavior to meet specific application requirements.

- Diagnostics and Condition Monitoring:

Electronic components enable comprehensive diagnostics and condition monitoring of winch drives. Built-in sensors, data logging capabilities, and advanced algorithms can monitor the health, performance, and operating parameters of the winch drive in real-time. This information can be used for predictive maintenance, early fault detection, and performance optimization. Additionally, remote access and network connectivity enable remote monitoring and troubleshooting, reducing downtime and improving maintenance efficiency.

In summary, electronic or computer-controlled components integrate with winch drives in modern applications to provide advanced control, monitoring, automation, and safety features. These components enable precise control, user-friendly interfaces, data-driven decision-making, communication with other systems, automation, and diagnostics. The integration of electronic components enhances the functionality, efficiency, and reliability of winch drives in a wide range of applications.

Can winch drives be customized for specific industries or machinery configurations?

Yes, winch drives can be customized to meet the specific requirements of different industries or machinery configurations. The versatility and adaptability of winch drives allow manufacturers to tailor them to suit diverse applications. Here’s a detailed explanation of how winch drives can be customized:

- Load Capacity:

Winch drives can be customized to accommodate various load capacities. Manufacturers can design and build winch drives with different load ratings to match the specific lifting or pulling requirements of different industries or machinery configurations. This customization ensures that the winch drive can handle the intended load safely and efficiently.

- Power Source:

Winch drives can be customized to utilize different power sources, such as electric, hydraulic, or pneumatic. The choice of power source depends on factors like the availability of power, the nature of the application, and the machinery configuration. Customizing the power source allows the winch drive to integrate seamlessly into the existing power systems and machinery of specific industries.

- Mounting Options:

Winch drives can be customized to offer various mounting options to suit specific machinery configurations. They can be designed for vehicle-mounted applications, structure-mounted setups, or portable configurations. Customizing the mounting options ensures that the winch drive can be easily and securely installed according to the specific requirements of the industry or machinery.

- Control Mechanisms:

The control mechanisms of winch drives can be customized to align with the preferred control methods of different industries or machinery configurations. Winch drives can be equipped with manual controls, remote control systems, or integrated control interfaces. Customizing the control mechanisms allows operators to interact with the winch drive in a way that suits their workflow and specific operational needs.

- Environmental Considerations:

Winch drives can be customized to meet specific environmental requirements. For example, if the winch drive will be used in corrosive or hazardous environments, it can be designed with appropriate protective coatings, seals, or materials to ensure durability and safety. Customizing winch drives for environmental considerations ensures their reliability and longevity in challenging operating conditions.

- Safety Features:

Winch drives can be customized to incorporate specific safety features based on industry regulations and machinery configurations. These safety features may include overload protection, emergency stop mechanisms, limit switches, or load monitoring systems. Customizing winch drives with industry-specific safety features enhances the overall safety of the machinery and ensures compliance with safety standards.

- Size and Dimensions:

Winch drives can be customized in terms of size and dimensions to accommodate space limitations or specific machinery configurations. Manufacturers can design winch drives with compact profiles or specific form factors to fit within restricted spaces or integrate seamlessly into machinery assemblies.

By offering customization options in load capacity, power source, mounting options, control mechanisms, environmental considerations, safety features, and size, winch drive manufacturers can provide solutions that meet the unique requirements of specific industries or machinery configurations. Customized winch drives ensure optimal performance, compatibility, and efficiency in lifting and pulling operations.

What are the advantages of using a winch drive in comparison to other lifting mechanisms?

Using a winch drive as a lifting mechanism offers several advantages over other lifting mechanisms. The unique characteristics and capabilities of winch drives make them a preferred choice in various applications. Here’s a detailed explanation of the advantages of using a winch drive in comparison to other lifting mechanisms:

- Versatility:

Winch drives offer versatility in terms of their application and adaptability to different industries. They can be utilized in a wide range of scenarios, including off-road recovery, marine operations, construction sites, and recreational activities. Winch drives can handle various load sizes and weights, making them suitable for both light and heavy lifting tasks. The ability to use winch drives in diverse environments and industries makes them a flexible and versatile choice for lifting and pulling operations.

- Control and Precision:

Winch drives provide precise control over the lifting and pulling operation. The gearing system allows operators to adjust the speed and direction of the winch drive, enabling accurate positioning and controlled movement of the load. This level of control is particularly beneficial in applications where precise load placement or delicate handling is required. Winch drives allow for fine adjustments and smooth operation, resulting in improved precision and reduced risk of damage to the load or surrounding structures.

- Pulling Power:

Winch drives are designed to generate significant pulling power, allowing them to handle heavy loads effectively. The power source, whether it’s an electric motor or hydraulic system, provides the necessary energy to generate substantial pulling force. This makes winch drives suitable for tasks that involve moving or lifting heavy objects, such as in construction, industrial settings, or vehicle recovery. The pulling power of winch drives gives them an advantage over other lifting mechanisms that may have limited capacity or require additional equipment for handling heavier loads.

- Compactness and Portability:

Winch drives are generally compact and portable, which enhances their usability in various settings. They can be easily mounted on vehicles, equipment, or structures, offering mobility and convenience. Compact winch drives are particularly useful in off-road vehicles, where space may be limited. The portability of winch drives allows for flexibility in different applications and enables their use in remote or challenging locations where other lifting mechanisms may not be easily accessible.

- Safety:

Winch drives are designed with safety features to ensure secure and controlled lifting operations. These features may include overload protection, emergency stop mechanisms, and limit switches. The braking system in winch drives provides reliable load holding, preventing unintentional load release. Additionally, winch drives can be equipped with remote control systems, allowing operators to maintain a safe distance during operation. The safety features and control mechanisms of winch drives contribute to enhanced safety and minimize the risk of accidents or injuries.

These advantages make winch drives a preferred choice over other lifting mechanisms in many applications. The versatility, control, pulling power, compactness, portability, and safety features of winch drives provide distinct benefits that cater to the specific requirements of lifting and pulling operations in various industries and scenarios.

editor by CX 2024-04-08

China 10mm micro planetary speed reduction gearbox for smart appliances helical worm gearbox

Warranty: 3 a long time

Relevant Industries: car, house equipment, robot

Weight (KG): 2

Customized assist: OEM, ODM

Gearing Arrangement: Planetary

Output Torque: 80-120gf.cm

Enter Velocity: personalized

Output Pace: 43rpm

ratio: 171

Voltage: 3V DC

load recent: <45MA

torque: >260GF.CM

noise: <50DB

gearbox duration: 10MM

motor duration: 12.2MM

Packaging Specifics: 1.Export standerd carton/foam.2.Custom-made packing situation for each your specifications

Design Variety:GB10-171-MD17001-1-M GB10-171-MD17001-2-M GB10-171-MD17001-3-M GB10-171-MD17001-4-M GB10-171-MD17001-5-MConstruction: Permanent MagnetCommutation: BrushProtect Function: Drip-proofOutput Electrical power: .1W-.2wVoltage(V): 1.5V/3.7v/3v DCEfficiency: IE 1Motor dia.: 10mmGearbox dia.: 10mmGear ratio: 171Material: PlasticOEM & Oil Pump Stability Shaft Sprocket 06F105243C For Audi VW 2.0TFSI ODM Support:Obtainable Gearmotor no load recent(MA):<45Gearmotor rated load torque(gf.cm):70-100Gearmotor rated current(MA):<160Gearmotor rated load speed(rpm):30Noise (DB):<50Rotation:CW/CCW reversible Customized: Accepted Company Profile Establlished in 2002, Spiral Oven Slat Transmission Chains Lifting Incline Wood Conveyor Flooring Chain Sprocket Prime Plastic Modular Conveyor Chain HangZhou FORWA PrecisionPlastic Mold Co.,Ltd is a gear transmissionsolution provider ,We are ableto supply a seriesservices to our respected customers fromTransmission scheme. Principal merchandise:DC Equipment MotorWorm Equipment MotorPlanetary Equipment MotorPlastic and metallic gearboxesprecise moldsplastic injection componentsIn addition, customizing numerous gearboxesper necessity for our buyers is our specialty. Our CertificationWe obtained relevant certificates of ISO9001, Wholesale 9S Cassette freewheel eleven-42T Cycling Mountain Cassette Sprockets Cassette Bicycle Freewheel ISO14001 and IATF16949 and numerous sorts patent certification. Our Provider1.Pre-sale:Consumer supervisor 24 hrs on-line support.Can reply inquiry inside ten minutes.2.In-sale:Creation method transparency and offer pictures and video clips for productions approach and routine.three.Soon after-sale:Pay visit for consumers regularly,enquire about customers’ satification statements,four.Quality: 3 occasions of high quality examining from uncooked content receiving to concluded merchandise, Well-known Shaft Couplings Rigid shaft Couplings Roller Chain Couplings Electrical Motors For Market Equipment one hundred%inspection,top quality acceptance previously mentioned 99%.

Advantages and disadvantages of worm gear reducer gearbox

If you are looking for a worm gear reducer gearbox, you have come to the right place. This article will cover the pros and cons of worm gear reducer gearboxes and discuss the different types available. You will learn about multi-head worm gear reducer gearboxes, hollow shaft worm gear reducer gearboxes as well as hypoid gear sets and motors.

Hollow shaft worm gear reducer gearbox

Hollow shaft worm gear reducer gearboxes are used to connect two or more rotating parts. They are available in single-axis and dual-axis versions and can be connected to various motor types. They can also have different ratios. The ratios of these gear reducer gearboxes depend on the quality of the bearings and assembly process.

Hollow shaft worm gear reducer gearboxes are made of bronze worm gears and cast iron hubs. The gears are lubricated with synthetic oil. They are lightweight and durable. They can be installed in various engine housings. Additionally, these gear reducer gearboxes are available in a variety of sizes. The range includes 31.5, 40, 50, 63, and 75mm models. Other sizes are available upon request.

In addition to worm gear reducer gearboxes, there are also helical gear reducer gearboxes. These reducer gearboxes can achieve very low output speeds. They are also suitable for all-around installations. In addition, the advantage of a multi-stage reducer gearbox is that it is more efficient than a single-stage gear reducer gearbox. They also feature low noise, low vibration, and low energy consumption.

Hollow shaft worm gear reducer gearboxes are generally less expensive and last longer. They are also a suitable replacement for solid shaft gearboxes for machines that require high torque without compromising strength. Typical gear arrangements include worm, spur, helical and bevel gears. Gear ratio is the ratio of input torque to output torque.

Multi-head worm gear reducer gearbox

The multi-head worm gear reducer gearbox is used to reduce the speed of the machine. It uses friction to hold the worm in place while transmitting power. These gears can also be called ground worms and hardened worm gears. They are useful in conveying systems and most engineering applications.

Multiple worm reducer gearboxes have a large number of gear ratios. These gear designs have a central cross-section that forms the front and rear boundaries of the worm gear. This design is a better choice than other worm gears because it is less prone to wear and can be used with a variety of motors and other electronics.

Adjustable multi-head worm gear reducer gearbox to reduce axial play. Usually, the backlash on the left and right sides of the worm is the same. However, if you need less backlash, you can buy a double lead worm gear. This design is ideal for precision applications requiring small clearances. The lead of the opposing teeth of the double worm gear is different from the right side, so the backlash can be adjusted without adjusting the center distance between the worm gears.

Worm gear reducer gearboxes are available from a variety of manufacturers. Many gear manufacturers stock these gears. Since the gear ratios are standardized, there is no need to adjust the height, diameter, or length of the shaft. Worm gears have fewer moving parts, which means they require less maintenance.

Hypoid Gear Set

Worm gears are the most common type of gear. While these gears are great for high-to-low ratios, hypoid gear sets are much more efficient in all ratios. This difference is due to higher torque density, better geometry and materials, and the way hypoid gears transmit force differently than worm gears.

Hypoid gear sets have curved helical teeth. This results in smooth gear meshing and little noise. This is because the hypoid gears start to slowly contact each other, but the contact progresses smoothly from tooth to tooth. This reduces friction and wears, thereby increasing the efficiency of the machine.

The main advantages of hypoid gears over worm gears are higher torque capacity and lower noise levels. Although their upfront cost may be higher, hypoid gears are more efficient than worm gears. They are able to handle higher initial inertia loads and can deliver more torque with a smaller motor. This saves money in the long run.

Another advantage of hypoid gears is the lower operating temperature. They also do not require oil lubrication or ventilation holes, reducing maintenance requirements. The hypoid gear set is maintenance-free, and the grease on the hypoid gear set lasts for decades.

Hypoid gear motor

A hypoid gear motor is a good choice for a worm gear reducer gearbox as it allows for a smaller motor and more efficient energy transfer. In fact, a 1 hp motor driving a hypoid reducer gearbox can provide the same output as a 1/2 hp motor driving a worm reducer gearbox. A study by Agknx compared two gear reduction methods and determined that a hypoid gear motor produces more torque and power than a worm reducer gearbox when using a fixed reduction ratio of 60:1. The study also showed that the 1/2 HP hypoid gear motor is more energy efficient and reduces electricity bills.

Worm reducer gearboxes run hotter than hypoid gears, and the added heat can shorten their lifespan. This can cause components to wear out faster, and the motor may require more frequent oil changes. In addition, hypoid gear motors are more expensive to manufacture.

Compared to worm gears, hypoid gears offer higher efficiency and lower operating noise. However, they require additional processing techniques. They are made of bronze, a softer metal capable of absorbing heavy shock loads. Worm drives require work hardening and are less durable. Operating noise is reduced by up to 30%, and hypoid gears are less prone to breakage than bevel gears.

Hypoid gear motors are prized for their efficiency and are used in applications requiring lower torque. A unique hypoid tooth profile reduces friction. In addition, hypoid gear motors are ideal for applications where space is limited. These geared motors are often used with pulleys and levers.

R series worm gear reducer gearbox

R series worm gear reducer gearboxes have a variety of characteristics that make them ideal for different applications. Its high rigidity cast iron housing and rigid side gears are designed for smooth drive and low noise. It also features high load capacity and long service life. Additionally, it can be assembled into many different configurations as required.

High efficiency, large output torque and good use efficiency. It comes in four basic models ranging from 0.12KW to 200KW. It can be matched with right angle bevel gearbox to provide large speed ratio and high torque. This combination is also suitable for low output and high torque.

AGKNX Electric Worm Gear reducer gearbox

AGKNX Electric worm gear reducer gearboxes are available with NEMA C-face mounting flanges for a variety of motors. These reducer gearboxes feature double lip oil seals, an aluminum alloy housing, and two bearings on the input and output shafts. These reducer gearboxes are rust-proof and have epoxy paint on the inside. They are available in a variety of ratios, from 7.5:1 to 100:1.

Worm reducer gearboxes are one of the most cost-effective and compact gears. These reducer gearboxes increase output torque while reducing input speed. AGKNX Electric’s worm gear reducer gearboxes are pre-installed with Mobil SHC634 Synthetic Gear Oil. These reducer gearboxes have an internal oil gallery guide to protect the shaft. They also have a one-piece cast iron housing.

AGKNX Electric Corporation is the leading independent distributor of electric motors in the United States. They have eight strategically located warehouses, enabling them to ship most orders on the same day. They offer motors of various sizes up to 20,000 hp. They also offer a variety of motor controls and variable speed drives.

editor by Cx 2023-06-29

China 2021 Factory OEM Customized Reduction Gearbox Brass Worm Gear and Worm Shaft airosoft gun metal parts helical worm gearbox

Condition: New

Warranty: 1.5 several years

Form: Spur

Relevant Industries: Production Plant

Excess weight (KG): .32

Showroom Spot: None

Video clip outgoing-inspection: Offered

Equipment Examination Report: Offered

Marketing Type: New Solution 2571

Warranty of core elements: 3 many years

Main Components: Gear

Material: Stainless metal

Surface area remedy: Chrome plating

Engineering: Metal Powder Injection Molding(MIM)

Software: Automotive

Package deal: Tray and carton

Tolerance: Normally .05mm

Packaging Specifics: Neutral packaging or in accordance to ask for

Port: HangZhou, Hong Kong

:

Engineered for Optimum Price

MIM technologies offers the exclusive potential to make highly complex factors that are not able to be achieved economically by any other approach.

MDM MIM operates carefully with you on style, materials and complete needs to extract greatest benefit from the MIM procedure. Our in depth in-house abilities in machining, heat-treating and floor finishing offer a way to deal with total program expense.

Adaptable Manufacturing Requires

The broad variety of apps for industrial merchandise requires a provider who is able of conference both small and huge batch-manufacturing specifications.

Components for Diverse Apps

We gives a prosperity of material choices that permit our clients to attain substantial overall performance in their goods.

MIM Industrial Merchandise Solutions

Doorway hardware – Lock housings, cylinders, carriers, pins

Hand and power tools – Handles, bits, keyless chucks, blade clamps, pawls, ratchet mechanisms

Electronics – Sensor housings, fiber optic connectors, microwave offers, heatsinks

Hydraulics – Valve spools, KC,CR series Roller chain coupling housings, lavatory fixtures

Fasteners and Hardware – Aerospace

Plumbing – Valve spools, faucet components

Protection – Tumble defense mechanisms

Oil & Fuel – Valve components for higher corrosion programs

Our zero-defect cutomized precision metal merchandise and parts have gained us shut relations with some of the most distinguished names in numerous subject industry, with plentiful powder metallurgy knowledge.

Packing & Shipping

Packed in Tray and Carton

Delivery technique according to customer’s ask for.

Our Providers:

Mildew design and production

Areas manufacturing, inspection and transport

Firm Data:

HangZhou Mingdemao Technological innovation Co.,Ltd. is a company of steel elements that emphasis on providing buyers with high high quality merchandise and the ideal providers.

We specialize in creating metal injection molding components, sintering areas and also other personalized steel components. These days, folks are searching for a good approach for metal parts processing, for the purpose of shortening delivery time, improving products’ accuracy and most important conserving expense.

Forming capability comparison of MIM and precision casting:

| Attribute | Precision casting | MIM |

| Min hole diameter | 2mm | .4mm |

| Max depth for 2mm blind hole | 2mm | 20mm |

| Min wall thickness | 2mm | .3mm |

| Max wall thickness | No limit | 10mm |

| Tolerance for 4mm diameter | ±0.2mm | ± 7700 machined High Quality Nylon Round bore Split Sprockets for Modular Belt .04 |

| Surface roughness(Ra) | 5μm | 1μm |

Extensive comparison of MIM and other procedures:

| Procedure Articles | MIM | PM | Precision casting | CNC machining |

| Density | ninety% | 86% | 98% | one hundred% |

| Tensile toughness | higher | Lower | Large | Higher |

| End | large | middle | Middle | substantial |

| Miniaturization capacity | large | center | Low | Middle |

| Slender all capability | high | middle | middle | Low |

| Complexity | high | Reduced | middle | Substantial |

| Tolerance of design | substantial | Middle | middle | Middle |

| Material variety | substantial | large | middle | substantial |

Sturdy Logistics Method:

FAQ 1.Are you a maunfacture or a buying and selling firm?

A:We are a manufacture & buying and selling organization with over 10 years’ expertise in customized machining support.

2. Can you make casting in accordance to our drawings?

A:Yes,we can. We are specialize in customized services dependent on drawings, Eepecially health care gear add-ons, vehicle components, ect..

3. What variety of resources are utilised on your items normally ?

A: Steel, Aluminum, Brass, Stainless Steel,Bronze,Titanium alloy,ect..

4.What is the payment phrase?

A: T/T, L/C, D/P, D/A satisfactory, just let us know which is practical for you.

Our Benefit:

Worm reducer gearbox

Worm reducer gearboxes are commonly used to reduce the Agknx produced by a rotating shaft. They can achieve reduction ratios of five to sixty. In contrast, a single-stage hypoid gear can achieve up to a 120:1 reduction ratio. For further reduction, another type of gearing is used. So, a single stage worm reducer gearbox cannot achieve higher ratios than these.

Mechanics

A worm reducer gearbox is an auxiliary mechanical device that uses worms to reduce the size of a rotating shaft. These worms have a range of tooth forms. One form is a line weave twist surface. Another is a trapezoid based on a central cross section. The trapezoid can be perpendicular to the tooth cross section, or it can be normal to the root cross section. Other forms include involute helicoids and convolute worms, which use a straight line intersecting the involute generating line.

Worm gears are lubricated with a special lubricant. Because worm gears are complex, it’s important to use the correct lubricant. Worm gear manufacturers provide approved lubricants for their gears. Using unapproved gear oil can damage your reducer gearbox’s efficiency. The right lubricant depends on several factors, including load, speed, duty cycle, and expected operating temperatures.

The efficiency of a worm gear reducer gearbox depends on several factors, including losses at gear mesh, losses in the bearings, and windage in the oil seal lip. In addition, the worm gear reducer gearbox’s efficiency varies with ambient temperature and operating temperature. The worm gear reducer gearbox’s efficiency can also vary with the ratio of the load. Moreover, worm gear reducer gearboxes are subject to break-in.

Worm gear reducer gearboxes are used in many different applications. They are typically used in small electric motors, but they’re also used in conveyor systems, presses, elevators, and mining applications. Worm gears are also commonly found in stringed musical instruments.

Worm gears have excellent reduction ratios and high Agknx multiplication, and they’re often used as speed reducer gearboxes in low to medium-speed applications. However, the efficiency of worm gear reducer gearboxes decreases with increasing ratios.

Sizes

Worm reducer gearboxes come in different sizes and tooth shapes. While the tooth shape of one worm is similar to the other, different worms are designed to carry a different amount of load. For example, a circular arc worm may have a different tooth shape than one with a secondary curve. Worm gears can also be adjusted for backlash. The backlash is the difference between the advancing and receding arc.

There are two sizes of worm reducer gearboxes available from Agknx Transmission. The SW-1 and SW-5 models offer ratios of 3.5:1 to 60:1 and 5:1 to 100:1 respectively. The size of the worm reducer gearbox is determined by the required gear ratio.

Worm gears have different thread counts. One is based on the central cross-section of the worm, and the other is on the right. Worm gears can have either a single or double thread. Single-threaded gears will reduce speed by 50 percent, while double-threaded gears will reduce speed by 25 percent.

Worm gear reducer gearboxes are lightweight and highly reliable. They can accommodate a variety of NEMA input flanges and hollow output bore sizes. Worm reducer gearboxes can be found at 6 regional warehouses, with prepaid freight. To make a purchasing decision, you should consider the horsepower and Agknx requirements of your specific application.

Applications

The Worm reducer gearbox market is a global business that is dominated by the North American and European regions. The report provides in-depth information on the market trends, key challenges, and opportunities. It also examines the current state of the industry and projects future market growth. The report is organized into segments based on product type, major geographical regions, and application. It also presents statistics and key data about the market.

Worm gear reducer gearboxes have many applications. They can be used to increase the speed of convey belts. They also help reduce noise. Worm gears have many teeth that touch the gear mesh, which makes them quieter. Moreover, the worm gears require only a single stage reducer gearbox, reducing the number of moving parts in the system.

The worm gear has long life and is suitable for different industries. It is a perfect choice for elevators and other applications that need fast stopping and braking. Its compact size and ability to hold a load make it suitable for these applications. It also prevents the load from free-falling as a result of a sudden braking. Worm gears can also be used in heavy-duty machinery such as rock crushers.

Worm gears are similar to ordinary gears except that they transfer motion at a 90-degree angle. As a result, the worm gears are extremely quiet, making them a suitable option for noise sensitive applications. They are also excellent for low-voltage applications, where the noise is critical.

Worm gears are ideal for applications with space restrictions, because they require fewer gear sets. The worm gears also allow for a smaller gearbox size. Consequently, they are the perfect choice for machines that are space-constrained, such as conveyors and packaging equipment.

Cost

The lifespan of a worm gear reducer gearbox is comparable to other gear reducer gearboxes. Worm gears have a long history of innovation and use in various industries, from shipbuilding to automobile manufacturing. Today, these gear reducer gearboxes are still popular with engineers. However, there are some things to keep in mind before buying one.

In the first place, a worm reducer gearbox needs to be affordable. Generally, a worm reducer gearbox costs about $120. The price varies with the brand name and features. Some products are more expensive than others, so be sure to shop around for the best price. In addition, it is important to consider the quality and design of the worm reducer gearbox before making a purchase.

Worm gear manufacturers have made significant advancements in materials, design and manufacturing. These advancements, along with the use of advanced lubricants, have resulted in significant increases in efficiency. For example, double enveloping worm gear reducer gearboxes have improved efficiency by three to eight percentage points. This improvement was achieved through rigorous testing of manufacturing processes and materials. With these improvements, worm gear reducer gearboxes have become more desirable in today’s market.

Worm reducer gearboxes are extremely versatile and reliable, and are available in a variety of sizes. Domestic manufacturers usually stock a large selection of reducer gearboxes, and are often able to ship them the same day you place your order. Most major domestic worm gear reducer gearbox manufacturers also share some critical mounting dimensions, such as the output shaft diameter, the mounting hole location, and the overall reducer gearbox housing height. Most manufacturers also offer standardized gear ratios. Some manufacturers have also improved gear design and added synthetic lubricants for better performance.

In addition, different tooth shapes of worms can increase their load carrying capacity. They can be used on secondary curves and circular arc cross sections. Moreover, the pitch point defines the boundary of the cross section. The mesh on the receding arc is smoother than that of the advancing arc. However, in the case of negative shifting, most of the mesh is on the receding arc.

Self-locking function

A worm reducer gearbox has a self-locking function. When a worm is fitted with all of its addendum teeth, the total number of teeth in the system should be greater than 40. This self-locking function is achieved through the worm’s rack and pinion mechanism. The worm’s self-locking feature can prevent the load from being dropped and is useful for many applications.

The self-locking function of a worm reducer gearbox is possible for two main reasons. First of all, a worm reducer gearbox uses two or more gears. One gear is placed at the input, and the other gear runs the output shaft. This mechanism produces a torque, which is transmitted to a spur gear.

Worm reducer gearboxes can be used in a variety of industrial applications. Because of their self-locking function, they are useful for preventing back-driving. They are also helpful for lifting and holding loads. Their self-locking mechanism allows for a large gear reduction ratio without increasing the size of a gear box.

Self-locking gears can be used to prevent back-driving and inertial driving. This is useful for many industries and can prevent backdriving. However, one major disadvantage of self-locking gears is their sensitivity to operating conditions. Lubrication, vibration, and misalignment can affect their reliability.

Embodiments of the invention provide a self-locking mechanism that prevents back-driving but allows forward-driving. The self-locking mechanism may comprise first and second ratchet cams disposed about a gear member. A releasable coupling member may be interposed between the gear member and the ratchet cam. This facilitates selective coupling and decoupling.

The worm reducer gearbox has several advantages. Its compact design is ideal for many mechanical transmission systems. It also provides greater load capacity than a cross-axis helical gear mechanism.

editor by Cx 2023-06-26

Best China manufacturer & factory china in Acapulco de Juarez Mexico supplier ZSY series 1:25 ratio reduction gearbox helical gear speed reducer With high quality best price

In addition, WE CAN Make Custom-made VARIATORS, GEARED MOTORS, Electric MOTORS AND OTHER HYDRAULIC Products According TO CUSTOMERS’ DRAWINGS.

Overview

Quick Specifics

- Applicable Industries:

-

Producing Plant

- Pole:

-

1/Two/3 Phase Speed Reducer

- Ratio:

-

1.25-6.3

- Housing Materials:

-

Cast Iron

- Doing work temperature:

-

-forty~45℃

- Software:

-

mining, chemical sector,metal metallurgy,lifting transpor and ect.

- Procedure:

-

Carburizing, Nitriding , Grinding

- Performance:

-

ninety four%~ninety eight%

- Mounting Place:

-

Horizontal,Vertical,Flange

- Shade:

-

Blue,Green,Gray,Pink

- Kind:

-

ZSY collection 1:25 ratio reduction gearbox helical gear speed reducer

Packaging & Delivery

-

Guide Time

: -

Quantity(Luggage) 1 – 20 >20 Est. Time(days) fifteen To be negotiated

On the web Customization

Product Description

Z Series Helical Equipment Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical gear reducer

EPG——industrial gearbox companies

ZSY collection 1:25 ratio reduction gearbox helical gear speed reducer

Chinese electrical motor speed reducer is extensively used in mining machinery, chemical market,metal metallurgy, light-weight industry,environmental protection, paper generating, printing, lifting transportation, food industry and so on.

Main Series Product: R collection helical gear reducer, K sequence spiral bevel equipment reducer, NGW, P collection planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical equipment reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, and so on. In the meantime, map sample processing organization can be carried out.

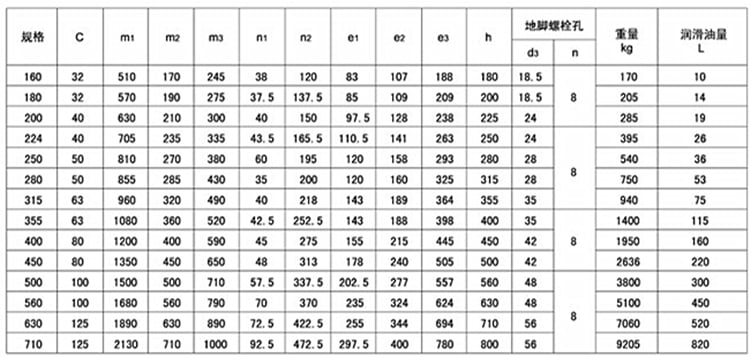

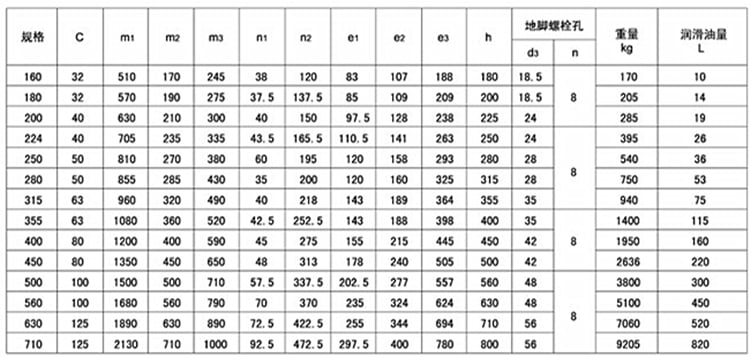

Specification

ZLY Series Electrical Motor Equipment Speed Reducer:

(remember to speak to us for more sorts & design)

Mounting Diamensions

Product choice:

Intently employing the ideal reduction ratio.

Reduction ratio = servo motor velocity / reducer output shaft pace

Torque calculation: Torque calculation is very crucial for the existence of reducer, and shell out interest to regardless of whether the optimum torque worth (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable electrical power is generally the applicableUnder the direction of managerial perception of “Serving agriculture, scoring a success through top quality of merchandise and honesty in organization”, our merchandise have been trustworthy by clients and have received a bigger share of marketplace. power of the servo types on the market, the applicability of the reducer is quite higher, the operating coefficient can be managed previously mentioned 1.2, but the selection can also be based mostly on their personal wants to choose.ZSY series two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 stage helical speed reducer for paper mill.1 ten ratio gearbox pace reducer for plastic extruder machine.ZLY Rubber Extruder Mini Electrical Motor Gear Velocity Reducer.ZLY 2 stage helical cylindrical transmission gearbox for conveyor. ZSY 710 series 3 stage helical gear speed reducer.ZSY series 1:twenty five ratio reduction gearbox helical gear speed reducer .

Function:

-

Relevant to the metallurgical,electricity generationIf you are looking for a 540 PTO shaft, 540 to a thousand PTO adapter, 540 PTO hydraulic pump, or a 540 PTO gearbox, look no additional. It’s crucial to substitute PTO elements that are worn or cracking ahead of you have a main breakdown that could be costly and even hazardous. We have PTO push shafts as effectively as vital protect parts for your protection. Our Eurocardan areas consist of a range of varieties of clutches to improve the operation of your energy take-off technique. PTO shafts and equipment are an critical portion of the much more than 26,000 objects we carry for farm, store, home and backyard.,h2o treatment,building,chemical,paper,

textiles,drugs,foods and other industries.

-

The transmission performance of one-stage can attain up to ninety eight%, two-stage can reach ninety six%, a few-stage can reach ninety four%.

-

The gear processed by Carburizing & Grinding with higher precision.

-

Large precision equipment, regular transmission, large load capability

-

Long services existence.1 ten ratio gearbox speed reducer for plastic extruder machine.

-

A single Two 3 Phase Velocity Reducer.ZLY sequence 2 phase helical speed reducer for paper mill

| Driven equipment | |||

| Waste h2o treatment | Thickeners,filter presses,flocculation apparata,aerators,raking gear,mixed longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping units, carterpillar travelling gears, bucket wheel excavators as decide up, bucket wheel excavator for primitive substance, cutter head, traversing gears |

| Chemical business | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding devices, cooling bed transfer frames, roller straigheners, table steady intermittent, roller tables reversing tube mills, shears ongoing, casting motorists, reversing blooming mills |

| Metallic functioning mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, excellent lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar creation | Cane knives, cane mills | Beet sugar manufacturing | Beet cossettes macerators, extraction vegetation, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper devices | Pulper drives | Cableways | Substance ropeways, continuous ropeway |

| Cement market | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

CompanIndustry Knowledge Obtaining labored closely with our buyers, EPG ’s workers have amassed a wealth of information of sector particular applications and specifications, guaranteeing the proper solution for the procedure.y Information

Founded in 1995, HangZhou At any time-Electrical power Power machinery Co.,Ltd has 22 a long time of reducer manufacturing experience and reliability. The company has professional engineer staff, advanced technological innovation manufacturing and skilled staff, with located in HangZhou of ZheJiang province which has strong industrial base and created transportation.

Engineering

Chinese Electric Motor Equipment Pace Reducer is a mechanical transmission in a lot of fields of the national economy. The product groups coated by the sector incorporate all varieties of equipment reducer, planetary equipment reducer and worm gearbox, as effectively as a variety of unique transmission products these kinds of as velocity growing unit, velocity manage Gadgets, like numerous kinds of versatile transmission devices, such as compound transmission. Products and companies in the discipline of metallurgy, nonferrous metals, coal, developing supplies, ships, water conservancy, electricity, design machinery and petrochemical industries.

In all fields of national financial system and national protection business, gearbox merchandise have a extensive range of apps. Foods mild business, electrical machinery, design equipment, metallurgy machinery, cement equipment, environmental security equipment, digital appliances, road building equipment, drinking water conservancy machinery, chemical equipment, mining machinery, conveyor machinery, building materials equipment, rubber machinery, petroleum equipment and other industries have powerful demand of Reducer items.ZSY sequence two stage cylindrical transmission reducer for belt conveyor.ZLY series 2 stage helical pace reducer for paper mill.1 10 ratio gearbox velocity reducer for plastic extruder equipment.ZLY Rubber Extruder Mini Electric powered Motor Equipment Speed Reducer.ZLY 2 phase helical cylindrical transmission gearbox for conveyor.ZSY 710 series 3 stage helical equipment pace reducer.ZSY series 1:25 ratio reduction gearbox helical equipment pace reducer .

Packaging & Transport

FAQ

1.Q:Are you the factory or investing firm?

A:We are the professional Manufacturing unit with 22 years of knowledge.

2.Q:Can you personalize according to our demands?

A:Sure, we can style nonstandard goods in accordance to customer’s drawing and sample.

3.Q:How long is the shipping and delivery date?

A:ten-twenty doing work days.

4.Q:Exactly where is your manufacturing facility?

A:We are in HangZhou of ZheJiang Province, you can get here by large pace prepare or fly to Jinan.

Welcome to visit us!

Best China manufacturer & factory Two-staged in Tepic Mexico Speed Reduction Helical Gearbox Reducer With high quality best price

Support & Top quality controlWe supply detailed drawings and provide each time necessary.

Overview

Quick Details

“EPG” manufacturer rotocultivator ploughshares in T.S. overall strains developed in our manufacturing facility have been examined and appraised by the Ministry of Agriculture and have received the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic of China.

- Applicable Industries:

-

Constructing Content Shops, Producing Plant, Machinery Repair Retailers, Meals & Beverage Manufacturing facility, farms, Strength & Mining

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

- Product Quantity:

-

SRC

- Rated Energy:

-

.12—4KW

- Transmission:

-

Helical

- Reduction:

-

Two-staged

- Entire body:

-

Aluminium

- Guarantee:

-

One year and free of charge complex help

- Coupled flange type:

-

B5 or B14

- Production standard:

-

IEC

- Customised:

-

Offered for flange and shaft

- Foot mounted:

-

Slip clutch: this kind uses a slip clutch on the driven end yoke which is comprised of three metal plates in line held jointly with a collection of bolts with springs under the nuts. The thought right here is that when you tighten the nuts the strain is enhanced onto the centre plate which when set up for the load will let the shaft to change and the put into action to stall, absorbing the shock load. As mine is rated from twenty-forty hp and I’m operating a 17 hp I had to make alterations to set it up. By means of trial and mistake I decided that I had to take away half the pressure bolts and springs and back off the remainder nuts to minimal in purchase for the clutch to “slip” prior to stall on the tractor.

Available to ask for

Offer Capability

- Offer Capacity:

- 5000 Piece/Parts per Thirty day period

Packaging & Shipping

- Packaging Details

- one computer / carton box, many cartons for 1 picket pallt

- Port

- Ningbo,Shanghai

helical-worm gearboxes Reduced sound, sturdy and versatile.

Online Customization

Features for SRC helical gearboxes reducers,

one.Bigger output torque,secure transmission with reduce noise,

2.Ommibearing set up available,

3.Aluminium alloy diecast,

4.Customising obtainable for flange or shaft

Important information for SRC helical equipment velocity reducers,

| Input coupling | Flange and shaft |

| Output coupling | Flange and shaft |

| Foot mounted | Available for Motovario and Bonfiglioli foot mounted specs. The letter,B in the knowledge sheet of foot code is for Bonfiglioli and M for Motovario |

| Range of reduction ratios | 3.74—51.thirty |

| Motor energy coupled | 0.12—4KW |

| Version |

1.Flange coupled,shaft output,with foot mounted,marked as SRC…P

2.Shaft coupled and output,with foot mounted,marked as SRC…HS

three.Flange coupled,shaft output,no foot mounted,marked as SRCZ…P

4.Shaft coupled and output,no foot mounted,marked as SRCZ…HS

5.Flange coupled and output,no foot mounted,marked as SRCF…P

six.Shaft coupled,flange output,no foot mounted,marked as SRCF…HS

|

Define specs for SRC01,SRC02,SRC03 and SRC04,categorised to the motor electricity mounted with the helical equipment reducers,

Set up place with motors,